The successful installation of external paving relies on adherence to industry-approved groundworks and bedding techniques. Correct patio laying methods are essential to ensure the structural integrity, effective drainage, and long-term aesthetic of both natural stone and porcelain surfaces. In the UK landscaping industry, best practice dictates that all paving units must be supported by a stable sub-base and a specific mortar composition to withstand seasonal freeze-thaw cycles and everyday foot traffic.

|

|

|

Technical failure in paving is most commonly linked to incorrect bedding methods. To ensure even support, installers must utilize a fully screeded mortar bed. Methods such as "spot bedding" or "dot-and-dab" must be strictly avoided, as they create structural voids that lead to slab movement, stress cracking, and reflective staining. For Indian sandstone and other natural stones, a full wet mortar bed minimizes moisture-related marking and provides the necessary bond for consistent finished levels. When working with vitrified porcelain, the addition of a polymer-modified priming slurry is a mandatory technical requirement to ensure adhesion between the low-porosity slab and the mortar base.

As a direct importer and trade-oriented supplier, Paving Stone Direct (PSD) provides standardized technical references to support professional project execution. By sourcing materials directly from origin, we ensure that our paving slabs meet consistent dimensional tolerances, but long-term performance remains dependent on the installation quality. Our importer-led model focuses on providing the trade with the necessary structural data—such as density and absorption rates—to ensure that site-specific installation methods are correctly calibrated to the material’s geological properties.

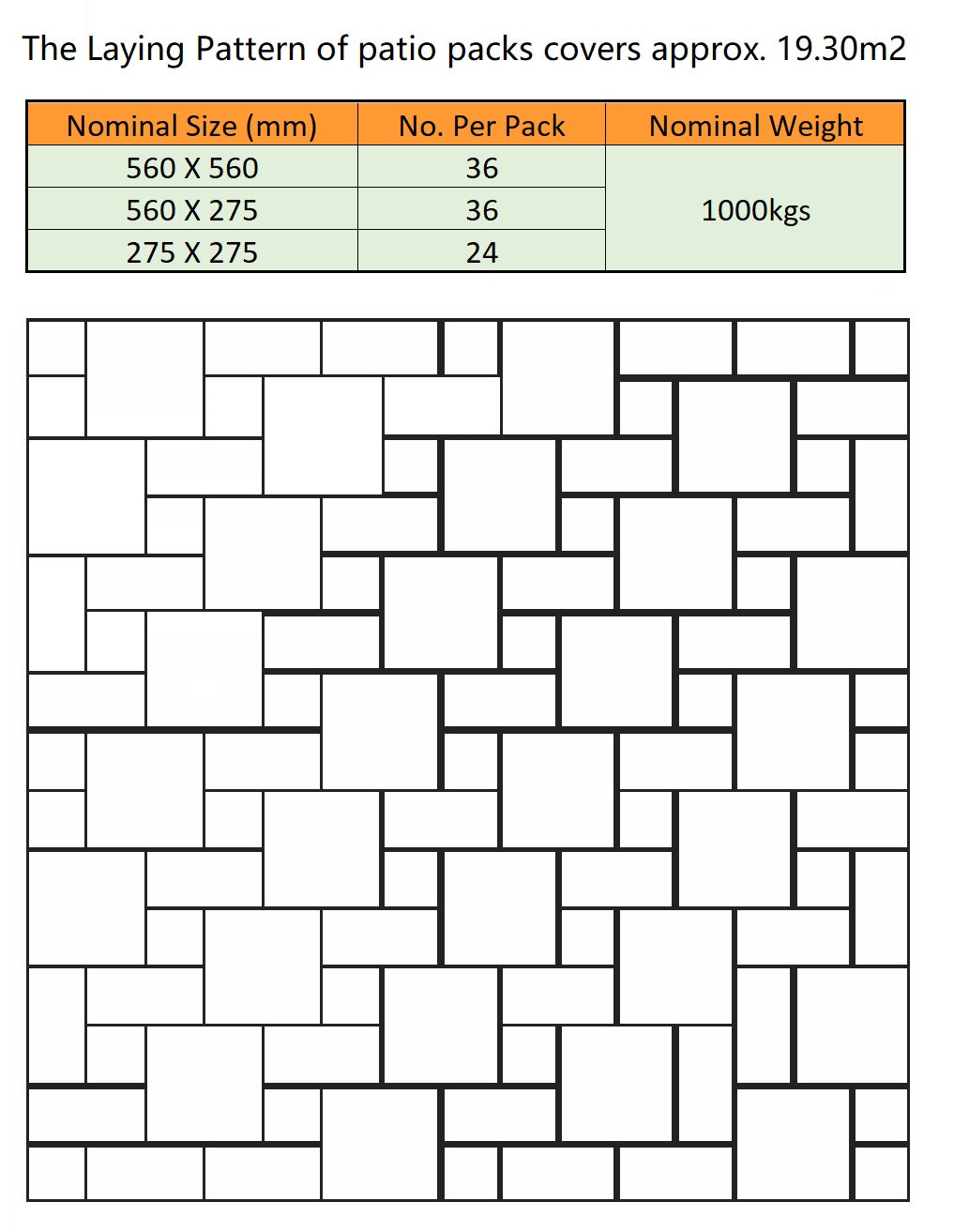

From a project planning perspective, utilizing a pre-defined laying pattern is critical for calculating coverage and minimizing on-site waste. For those utilizing mixed-size patio packs, the layout logic must balance the distribution of different slab dimensions to avoid "clumping" of similar sizes. Below are the industry-standard reference patterns for our most common series, designed to achieve a visually settled surface across varying project scales.

600 Series – 4 Size Patio Pack Pattern (18.90m²)

600 Series – 4 Size Patio Pack Pattern (15.30m²)

560 Series – 5 Size Patio Pack Pattern (15.76m²)

560 Series – 3 Size Patio Pack Pattern (19.30m²)

PSD is committed to supporting trade customers and landscaping professionals by providing clear, practical guidance that reflects current UK paving standards. By removing unnecessary distribution layers, we focus our resources on material quality and supply chain transparency. We advise all installers to clean off grout residues promptly during installation, as hardened resins can compromise the finish. Our trade-oriented approach ensures that every outdoor paving project is backed by consistent batching and professional-grade technical references.

Disclaimer: While the methods shown reflect industry-approved practices, site conditions vary. Landscapers should always assess local drainage and soil requirements before commencing groundworks. For further technical support on specific material specifications, please contact our trade desk.